A small intro video about the article:

Quality 4.0 is a concept that emerged as part of the Industry 4.0 revolution, which focuses on the integration of digital technologies into manufacturing processes. Quality 4.0 represents the application of digital technologies and data analytics to enhance quality management and assurance in the industrial sector.

With Quality 4.0, traditional quality control and assurance methods are augmented or replaced by advanced technologies such as artificial intelligence, machine learning, the Internet of Things (IoT), and big data analytics. These technologies enable real-time monitoring, predictive analysis, and proactive quality management.

Quality 4.0 aims to improve product quality, process efficiency, and customer satisfaction by leveraging data-driven insights. It involves collecting and analyzing data from various sources, including sensors, production equipment, supply chain systems, and customer feedback. The integration of these data sources allows for better quality control, faster identification of defects or anomalies, and more informed decision-making.

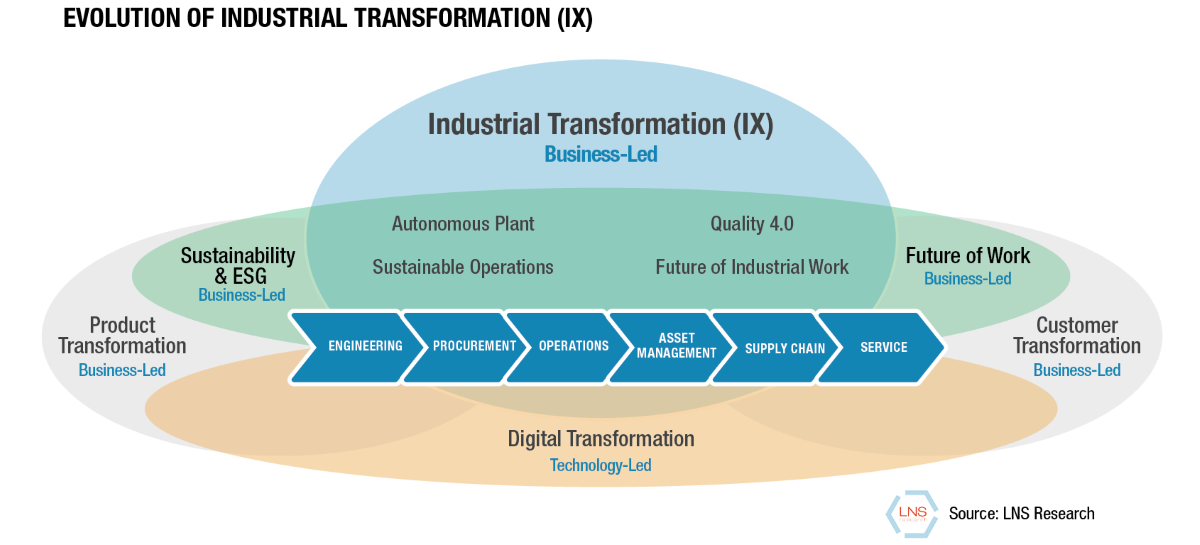

Here is the a diagram of evolution of industrial transformation:

Additionally, Quality 4.0 often incorporates concepts like continuous improvement, lean manufacturing, and agile methodologies. It emphasizes a holistic and proactive approach to quality management, where quality is built into the entire production process rather than relying solely on post-production inspection.

The key pillars of Quality 4.0 are :

1. Data-driven decision-making: Data lies at the core of Quality 4.0. This pillar emphasizes the collection, analysis, and utilization of data from various sources, including sensors, production systems, supply chains, and customer feedback. By harnessing data analytics techniques such as machine learning and AI, organizations can gain insights into quality trends, identify potential issues, and make informed decisions to optimize processes and enhance product quality.

2. Connectivity and interoperability: This pillar focuses on the seamless integration and connectivity of different systems, devices, and stakeholders across the value chain. By establishing digital connections between machines, software applications, and quality management systems, organizations can achieve real-time data exchange, collaboration, and coordination. It enables efficient communication, data sharing, and synchronization, fostering a holistic and interconnected quality ecosystem.

3. Smart and adaptive processes: Quality 4.0 encourages the implementation of smart and adaptive processes that can quickly respond to changing circumstances and requirements. This pillar emphasizes the use of advanced technologies such as automation, robotics, and AI to optimize quality management activities. Adaptive processes leverage real-time data and predictive analytics to enable proactive decision-making, self-correction, and continuous improvement, leading to increased flexibility and efficiency.

4. Customer-centricity and engagement: Quality 4.0 places a strong emphasis on meeting customer expectations and delivering superior customer experiences. This pillar recognizes the importance of understanding customer needs, preferences, and feedback throughout the product lifecycle. By actively engaging customers, gathering their insights, and integrating them into quality processes, organizations can align their products and services to customer expectations, improve satisfaction levels, and foster long-term loyalty.

Overall, Quality 4.0 represents a shift toward a more data-centric and technology-driven approach to quality management, enabling organizations to achieve higher levels of efficiency, flexibility, and customer satisfaction in their manufacturing processes.